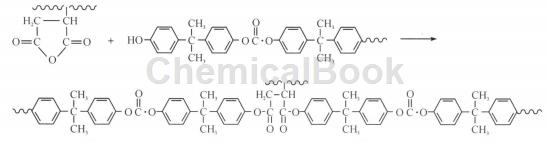

The main compatibilizers for Maleic Anhydride Grafted Compatibilizer are abs-g-mah, PE-g-MAH, PP-g-MAH and PS (SMA). The compatibilizing mechanism of this kind of compatibilizer is that maleic anhydride group in compatibilizer reacts with hydroxyl end of PC resin to form graft. The graft plays the role of compatibilizer, and the esterification reaction is as follows:

Abs-g-mah compatibilizer system: abs-g-mah compatibilizer is obtained by the direct reaction of ABS and maleic anhydride, and its main chain structure is the same as that of ABS. Therefore, abs-g-mah compatibilizer has good compatibility with ABS, which is generally the preferred compatibilizer for PC / ABS Blends. It is found that styrene / butadiene and styrene / acrylonitrile in unmodified ABS are mutually exclusive, while maleic anhydride in ABS gmah is mainly grafted on styrene / butadiene, which makes the polarity of grafted styrene / butadiene close to that of styrene / acrylonitrile, so that the polarity of ABS is similar to that of PC, which improves the compatibility of ABS / PC. The Tg of PC phase and San phase modified by abs-g-mah is lower than that of PC / ABS immiscible alloy system. The results show that abs-g-mah can increase the compatibility of PC / ABS Blends.

PE-g-MAH compatibilizing system: the main chain of maleic anhydride grafted polyolefin has good compatibility with ABS due to its similar structure with Pb in ABS. In addition, maleic anhydride group can also react with hydroxyl groups on the surface of PC, so maleic anhydride grafted polyolefin is also used as phase compatibilizer in PC / ABS Blend System, and shows good compatibilizing effect. It was found that the three glass transition temperatures of the blends changed regularly with the addition of PE-g-MAH. With the increase of PE-g-MAH content, TG (PB) increased, while TG (PC) and TG (SAN) decreased, indicating that PE-g-MAH improved the compatibility of PC / ABS Blends. The SEM images of the impact samples of PC / ABS Blends before and after adding PE gmah were compared. It was found that when no compatibilizer was added, the fracture surface of the blends was brittle and smooth. After adding compatibilizer, the fracture surface was rough, which was a typical ductile fracture feature. This shows that compatibilizer has a good compatibilizing effect on PC / ABS Blends.

PP-g-MAH compatibilizing system: the notched impact strength of PP-g-MAH compatibilizing PC / ABS Blend System was tested. It was found that the notched impact strength of samples appeared the highest point with the increase of PP-g-MAH content, and then decreased. This is because with the addition of compatibilizer PP-g-MAH, a stable transition zone is formed between PC and ABS, which improves the compatibility of the alloy and improves the notch impact strength of the alloy. Fang Shaoming et al. [28] pointed out that with the increase of MAH content in PP-g-MAH, the notched impact strength of the alloy decreased after the maximum value appeared. When MAH exceeded a certain amount, excessive MAH would cause its own homopolymerization, which was not conducive to grafting onto PP free radicals, and affected the compatibilization effect of PP-g-MAH on PC / ABS Blends.