The main difference is that Maleic Anhydride Modified PP is the modification of polypropylene, which can effectively make up for some shortcomings of polypropylene itself.

It can be understood in detail from the characteristics and preparation of polypropylene and maleic anhydride polypropylene:Maleic Anhydride Modified PP is a kind of modified polypropylene, which can also be regarded as acrylic acid.

Polypropylene is a thermoplastic resin made from propylene polymerization. According to the methyl arrangement, it can be divided into isotactic polypropylene, atactic polypropylene and syndiotactic polypropylene. In fact, maleic anhydride grafting is a kind of grafting formula. Maleic anhydride is selected as the monomer and grafted with some materials at a suitable temperature. Monomers can also be acrylic, etc.Polypropylene has distinct characteristics, which can be optimized by maleic anhydride grafting.

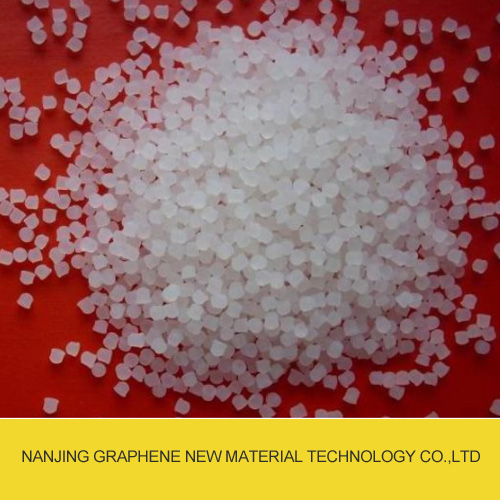

Polypropylene includes copolymers of propylene and a small amount of ethylene. It is usually a translucent colorless solid, odorless and nontoxic. It is highly crystallized due to its regular structure, with a melting point of 167 ℃. Heat resistant, corrosion-resistant, products can be steam disinfection is its outstanding advantages. It is the lightest general-purpose plastic with small density. The disadvantage is poor low temperature impact resistance, easy to aging, but can be overcome by modification, maleic anhydride polypropylene is one of them.Maleic anhydride polypropylene is prepared by reactive extrusion grafting maleic anhydride onto polypropylene

In other words, strong polar side groups are introduced into the main chain of non-polar molecules.Maleic Anhydride Modified PP can be a bridge to improve the adhesion and compatibility between polar and non-polar materials. Adding Maleic Anhydride Modified PP in the production of filled polypropylene can greatly improve the affinity and dispersion of filler and polypropylene. Therefore, it can effectively enhance the dispersion of filler in polypropylene, so as to improve the tensile and impact strength of filled polypropylene.