Description

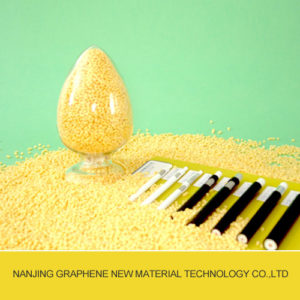

Foaming Nucleating Agent In Industry is designed to be extruded with LDPE or HDPE gas injection compounds for processing physical foaming insulated coaxial cables. It is normally added at 1-3% masterbatch concentration into a blend of 60-80% HDPE and 20-40% LDPE.

Foam nucleation masterbatch, Nucleating Agent characteristics:

Improve the anti-heating, rigidity and tightness property for XPS/EPS/PS.

Remove the surface light form of XPS/EPS/PS to get sub-light effect.

Improve the surface antifriction property of XPS/EPS/PS.

Reduce shrinkage ratio of final products to improve size stability.

Reduce fire heating quantity of XPS/EPS/PS to reduce the second pollution.

Improve the surface printing property of XPS/EPS/PS to reduce the electric current under surface corona process.

Improve heat-conduction property of XPS/EPS/PS to reduce the molding period.

Reduce the application ratio of white color masterbatch.