Classification and varieties of Maleic Anhydride Grafted Compatibilizer

Monday, 30 December 2019

(1) Mah type. Cyclic anhydrides are the most commonly used reactive compatibilizers. Among them, the main compatibilizer is maleic anhydride grafted on polyolefin, and its grafting rate is generally 0.8% – 1.0%, which is mainly used in the modification of polyolefin plastics. The Maleic Anhydride Grafted Compatibilizer of binary or multicomponent copolymerization of maleic anhydride

- Published in NEWS&BLOG

No Comments

Types and application of maleic anhydride graft compatibilizer

Tuesday, 24 December 2019

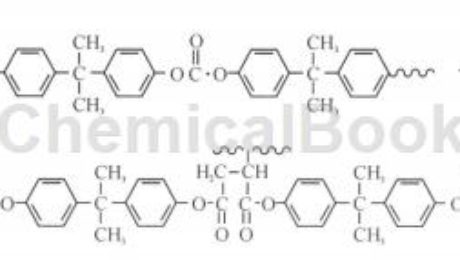

The main compatibilizers for Maleic Anhydride Grafted Compatibilizer are abs-g-mah, PE-g-MAH, PP-g-MAH and PS (SMA). The compatibilizing mechanism of this kind of compatibilizer is that maleic anhydride group in compatibilizer reacts with hydroxyl end of PC resin to form graft. The graft plays the role of compatibilizer, and the esterification reaction is as follows: Abs-g-mah

- Published in NEWS&BLOG

What is Maleic Anhydride Grafted EVA For Halogen-Free Flame Retardant

Tuesday, 24 December 2019

Maleic Anhydride Grafted EVA For Halogen-Free Flame Retardant, also known as compatibilizer, refers to the aid of intermolecular bonding force, to promote the two incompatible polymers to combine together, and then to obtain stable additives for blends, which refers to polymer compatibilizer. Good compatibilizer is usually grafted with maleic anhydride. Maleic anhydride monomer has strong

- Published in NEWS&BLOG

The difference between polypropylene and Maleic Anhydride Modified PP

Monday, 16 December 2019

The main difference is that Maleic Anhydride Modified PP is the modification of polypropylene, which can effectively make up for some shortcomings of polypropylene itself. It can be understood in detail from the characteristics and preparation of polypropylene and maleic anhydride polypropylene:Maleic Anhydride Modified PP is a kind of modified polypropylene, which can also be

- Published in NEWS&BLOG

The specific brand and application of Maleic Anhydride Grafted Compatibilizer are as follows

Monday, 16 December 2019

Maleic Anhydride Grafted Compatibilizer has high polarity and reactivity by introducing strong polar reactive groups. It can be used in flame retardant, reinforcement, toughening, filling, bonding, metal bonding, plastic modification, toughening and impact resistance, plastic alloy compatibility, engineering plastic modification, PA / PE toughening adhesive layer, PA and other toughening, ABS / PC, PBT /

- Published in NEWS&BLOG

Application of polyolefin grafted maleic anhydride as compatibilizer

Monday, 09 December 2019

Polyolefins (PE, PP, EPDM, EPR, EVA, etc.) have poor compatibility with other materials, such as polar polymers and inorganic fillers, because of their nonpolarity and crystallinity. By adding the compatibilizer prepared in advance or formed in situ, the original incompatible polymer can form a blend with unique properties that none of the components has. As

- Published in NEWS&BLOG

Application and synthesis of Maleic Anhydride Grafted Compatibilizer

Monday, 09 December 2019

Polymer alloy is a new type of polymer which has two (or more) advantages at the same time by mixing two (or more) polymers with different advantages through chemical and physical methods. Its excellent performance and broad development prospects make it more and more popular. In recent years, the development and industrial application of polymer

- Published in NEWS&BLOG

The contribution of Maleic Anhydride Grafted Compatibilizer to materials

Monday, 02 December 2019

Maleic Anhydride Grafted Compatibilizer, also known as compatibilizer, refers to the combination of two incompatible polymers by means of the bond force between molecules, so as to obtain stable additives for blends. Here, it refers to the polymer compatibilizer, which is applied in plastic modification to obtain blends with good performance. At present, good compatibilizer

- Published in NEWS&BLOG

Method of Foaming Nucleating Agent closed cell foam board

Monday, 02 December 2019

There are many ways of forming polyethylene foam, which are mainly extruded, moulded and granular. China mainly uses extrusion and molding to produce polyethylene foam.The extrusion method is to extrude the polyethylene containing Foaming Nucleating Agent from the die of the extruder head. When the melting material is reduced from high pressure to normal pressure,

- Published in NEWS&BLOG

What is Cable lining adhesive?

Monday, 25 November 2019

The Cable lining adhesive that produced by our company is a New materials for cold patching of cable joints. Power cable power supply is widely used in coal mine because of its advantages of safety, reliability and convenience for underground tunnel laying and maintenance. Operation experience shows that the intermediate joint of cable is the

- Published in NEWS&BLOG