Description

GNM101: it is a kind of foam stabilizer, activator, Nucleating Agent, Antioxidant, dispersant and so on. It has the characteristics of stable and uniform dispersion ratio in the base material, and has good compatibility with the base resin. With the help of screw shearing and mixing, it can rapidly spread in the polymer melt, thus promoting the nucleating agent to form evenly distributed “hot spots” in the polymer melt, locally reducing the melt surface tension and melt viscosity, so as to achieve the goal of making the foam pores of the molding material delicate . There is no difference between the processing temperature after adding GNM101 and the processing temperature of polymer itself, and the material flow performance is more, the production efficiency is higher.

Advantages:

- Superior dispersibility in plastic, rubber, etc..

- Decomposition temperatures suitable for plastic and rubber processing.

- Ability to control cells’ density and size.

- Low degradation over time; excellent storage stability.

Applications:

- Energy absorption, elastic functionality (cushioning)

- Sound absorption, automotive interiors

- Mechanical functionality (elasticity, flexibility)

- Light-weight applications

- Decorative (wallpaper, leather)

- Thermal (heat insulation)

Application fields: Physical Foaming Communication Cable and RF Cable Insulation layer of PP / PE / PTFE and other materials;

PP / PE Foamed Composite Board;

Need to foam bags, shoes and other products.

Manufacturers required (in order of emphasis): A. communication, coaxial, RF cable factory

b. Foaming Composite board factory (such as foaming aluminum plastic composite board, etc.)

C. Wood plastic factory

D. Luggage factory

E. Shoe factory

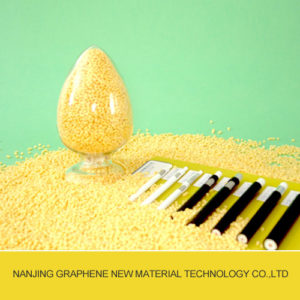

Product appearance: yellowish plastic particles